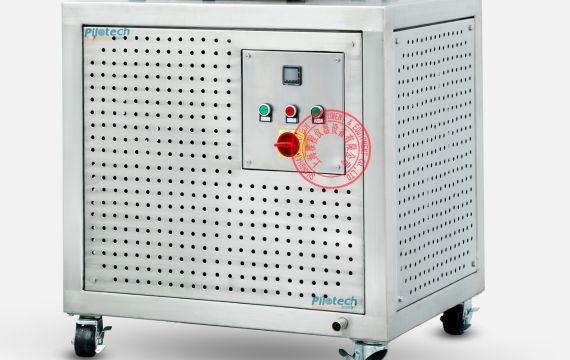

YC-501有机溶剂喷雾干燥机

- 最大处理量为500 ml/h。

- 干燥后粒径范围为1-25微米。

- 配备布袋过滤器,确保高效过滤。

- 适用于水溶液和大多数有机溶剂。

- 设备采用上下结构,模块化设计,便于维护和操作。

- 参数表

| 序列 | 参数 | 上海雅程YC-501有机溶剂喷雾干燥机 |

| 1 | 功率 | 2500W |

| 2 | 电压 | 220V; 单相; 50-60 Hz |

| 3 | 处理量 | 500ml/h |

| 4 | 额定风量 | 1.5mᶟ/min |

| 5 | 粒径范围 | 1-25µm |

| 6 | 最大进风温度 | 200⁰C |

| 7 | 加热器 | 1500W |

| 8 | 温度精度 | ±1⁰C |

| 9 | 喷嘴内径 | 标准1.0mm/(0.5/0.8/1.5/2.0mm 可选) |

| 10 | 喷雾头类型 | 二流体(三流体可选) |

| 11 | 最小样品量 | 10-20ml(与物料的固含量等因素有关) |

| 12 | 机器材质 | SUS304 不锈钢(SUS316不锈钢可选) |

二流体喷雾头

喷雾头为同心喷雾头,采用二流体(三流体可选配),雾化时确保没有任何偏心而导致喷到瓶壁一侧,喷雾头安装后可以上下移动,以利于调整雾化位置改善喷雾干燥效果,标配1.0mm喷嘴,其他尺寸可选配。

YC-501有机溶剂喷雾干燥机

完整指南

YC-501有机溶剂喷雾干燥机是一款既可以用于水溶液,也可以用于有机溶剂的喷雾干燥,它适用于大多数有机溶剂,例如甲醇,乙醇,丙酮,乙腈。

YC-501有机溶剂喷雾干燥机采用了一种模块化的结构,它分为上下两个部分,上面是喷雾干燥机主机,下面是氮气循环系统,制冷机内置在氮气循环系统里面。

那么为什么要这样做呢?

这样做的好处是当用于水溶液的喷雾干燥时,氮气循环系统是不用连接的,可以用氮气或者空气作为热风,在用空气作为热风时可以节省经费,不需要再另外购买氮气源。

当用于有机溶性喷雾干燥的时候,把喷雾干燥主机和氮气循环系统连接,用氮气作为热风的来源,确保了有机溶剂喷雾干燥的安全性。

YC-501有机溶剂喷雾干燥机用于有机溶剂时的工作原理是:

首先液体物料通过进料管进入,在喷雾头处被雾化成小液滴,小液滴与加热的空气或者是氮气接触,瞬间被干燥成粉末,在旋风分离器的作用下,粉末在收集罐处被收集,产生的尾气通过尾气管排出。尾气主要有三种成分,第一种是有机蒸气,第二种是氮气,第三种是粉尘颗粒, 首先粉尘颗粒会被布袋过滤装置收集,有机蒸气会被冷凝,冷凝后在溶剂回收罐处被收集,最后洁净的氮气进入下一个循环系统。

YC-501有机溶剂喷雾干燥机设计了溶剂排放口,当回收罐的溶剂满了之后,我们可以直接通过排放口排放,避免了因为回收罐满了之后需要停机的问题。

在系统里氧气含量会设定一个安全值,当系统内氧气含量高于安全值时,设备不能开机或者自动停机,来保证整个实验进程的安全。

YC-501有机溶剂喷雾干燥机的处理量是500ml/h,可以连续工作,最小处理量为10-20ml(与物料的固含量等因素有关),适用于实验室比较珍贵的物料或者是难以自备的物料。

技术参数

| 参数 | 上海雅程 YC-501 有机溶剂喷雾干燥机 |

| 功率 | 2500W |

| 电压 | 220V,单相, 50-60Hz |

| 最小出风温度 | 40℃(与溶剂的沸点有关) |

| 处理量 | 500ml/h |

| 额定风量 | 1.5 mᶟ/min |

| 最大进风温度 | 200⁰C |

| 加热器 | 1500W |

| 温度精度 | ±1⁰C |

| 喷嘴内径 | 1.0mm 标准/(0.5/0.8/1.5/2.0mm 选配) |

| 喷雾头类型 | 二流体(三流体可选) |

| 粒径范围 | 1-25µm |

| 平均停留时间 | 1.0-1.5 sec |

| 最小物料量 | 10-20ml(与物料的固含量等因素有关) |

| 干燥室材质 | SUS304 不锈钢(SUS316不锈钢可选) |

| 旋风分离器材质 | SUS304 不锈钢(SUS316不锈钢可选) |

| 收集罐材质 | SUS304 不锈钢(SUS316不锈钢可选) |

| 机器材质 | SUS304 不锈钢 |

| 密封圈材质 | 硅胶 |

| 气体类型 | 氮气 (有机溶剂)或者压缩空气(水溶液) |

| 尺寸 | 880*550*900mm(主机), 900*800*900mm(氮气循环系统) |

| 通针 | 自动 |

| 显示屏 | 7英寸 LCD触摸屏,用于显示加热、雾化、蠕动泵、压缩空气、通针频率 |

| 加热保护 | 直到温度低于90℃风机才会停止 |

| 氮气循环系统 (有机溶剂) | 有 |

YC-501有机溶剂喷雾干燥机是一款多功能且可靠的解决方案,专为实验室规模的喷雾干燥应用设计。它适用于处理水性和有机溶剂,采用模块化设计,配备先进的安全功能,确保实验过程高效且安全。使用 YC-501有机溶剂喷雾干燥机,您可以获得稳定、高质量的干燥结果。

立即联系上海雅程,了解更多关于 YC-501有机溶剂喷雾干燥机的信息,探索它如何助力您的研究与开发项目。我们的专业团队将为您提供全面支持,帮助您做出明智的选择,并在整个购买过程中为您保驾护航。

氮气循环系统以氮气作为干燥介质进行循环,有效消除有机溶剂干燥过程中爆炸或燃烧的风险。

YC-501有机溶剂喷雾干燥机的处理量为500ml/h,适用于小规模实验室应用和比较珍贵的或者是难以自备的物料。

YC-501有机溶剂喷雾干燥机可处理多种有机溶剂,包括甲醇、乙醇、丙酮和乙腈等。

YC-501有机溶剂喷雾干燥机的最小物料量为 10-20 ml(与物料的固含量等因素有关)。

YC-501有机溶剂喷雾干燥机使用氮气作为干燥介质,在系统里氧气含量会设定一个安全值,当系统内氧气含量高于安全值时,设备不能开机或者自动停机,来保证整个实验进程的安全。

定期维护包括检查系统、清洁布袋过滤器、检查和清洁喷嘴、以及确保冷凝器没有冰水堆积。

YC-501有机溶剂喷雾干燥机最高进风温度为200℃,可灵活满足各种干燥要求。

可以,我们提供定制选项,以满足特定实验室的需求。我们的专业团队会为您量身定制解决方案。

我们的交货时间通常为 25个工作日。此期间包括制造、质量检查和准备发货。

YC-50有机溶剂喷雾干燥机采用坚固的木箱包装,以防止运输过程中损坏。